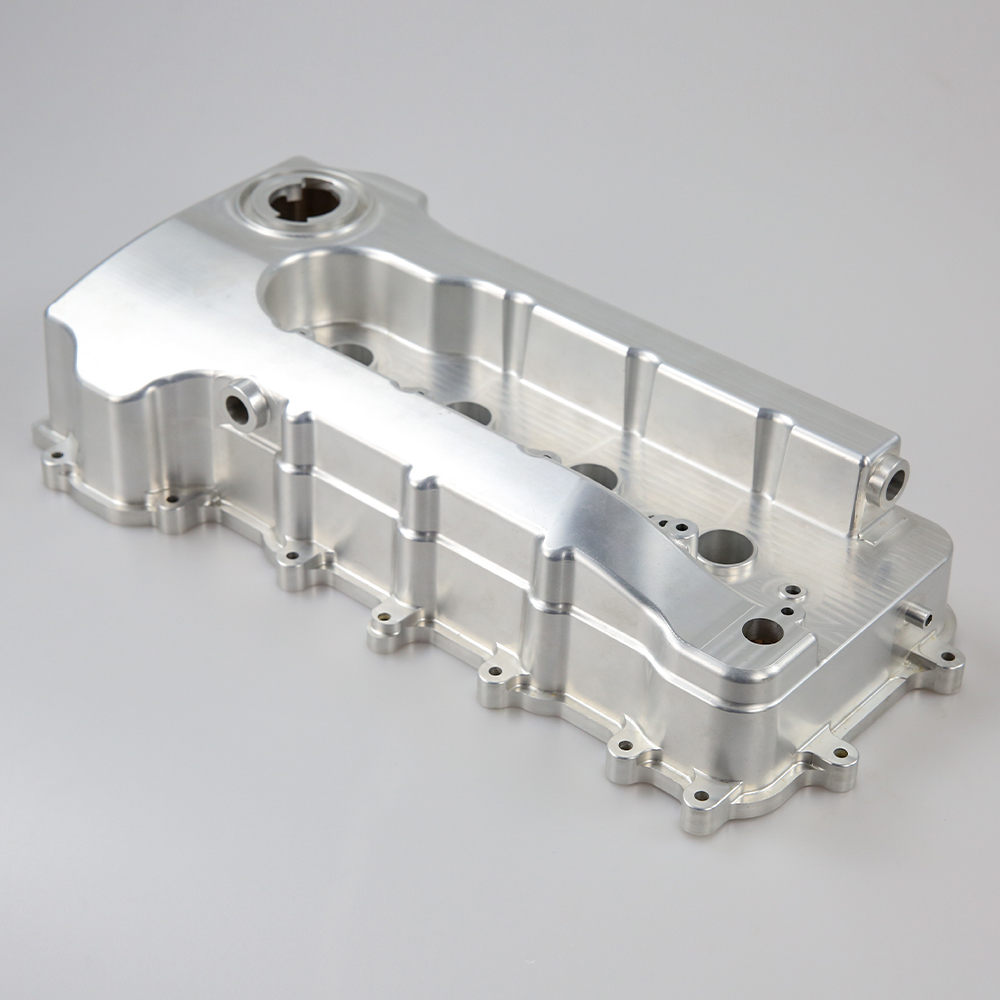

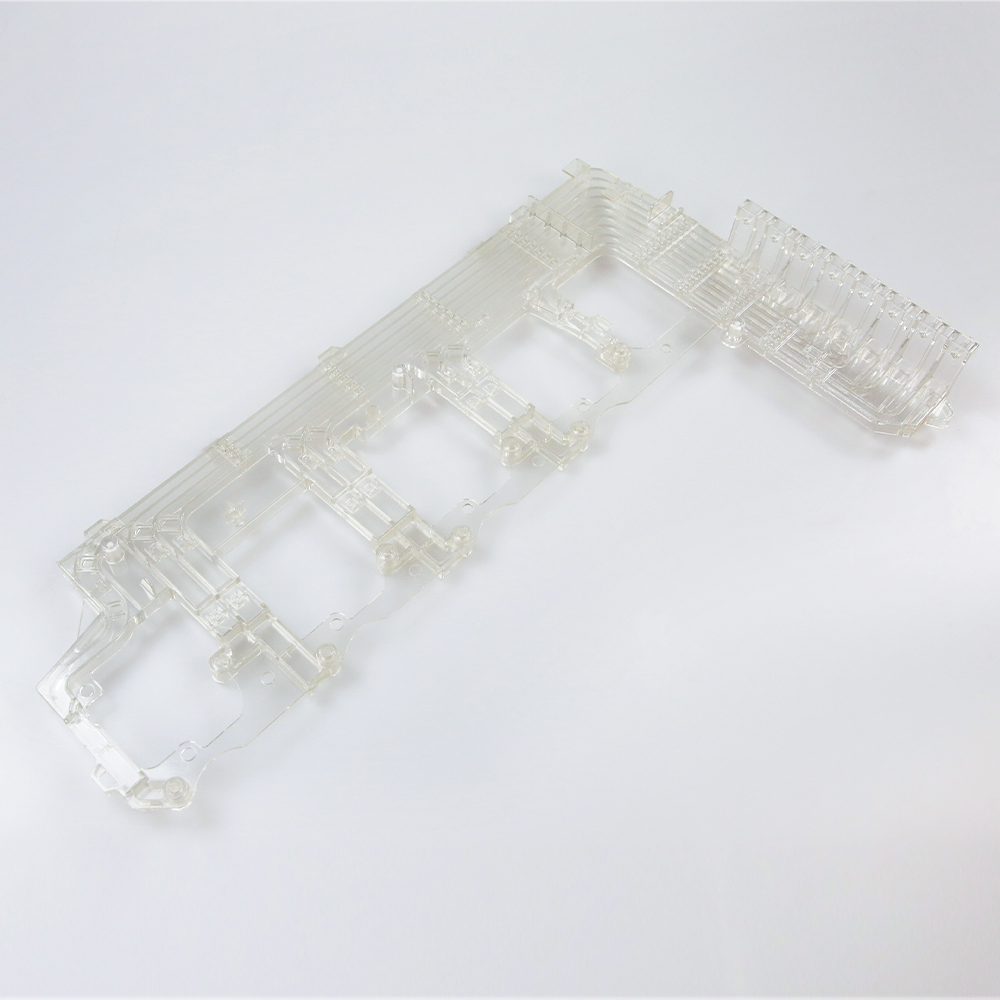

CNC precision machining

Keyo's CNC machining services can provide you with precision machining of any number of plastic and metal parts. Our specializations include milling, turning, EDM, wire cutting and surface grinding. We have 3-axis CNC machine tools, 4-axis CNC machine tools and 5-axis CNC machining centers. Our 3axis CNC machines can output maximum spindle speeds of up to 24,000 RPM and utilize 14 to 24 station automatic towers, enabling Keyo to provide customers with efficient CNC parts production. Whether you need hand samples or small batch production parts, our processing services are your better choice.

What are the advantages of CNC machining products?

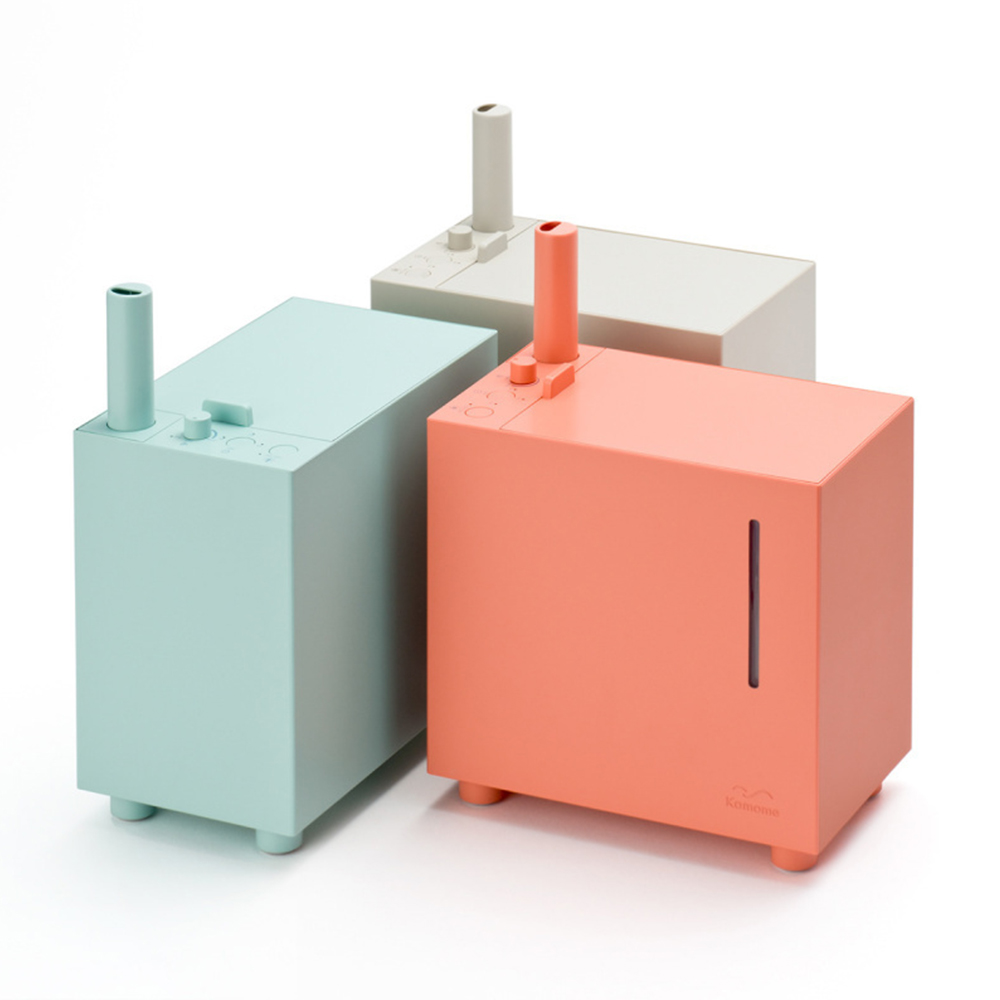

Show your customers and investors a mock-up of your product。

Show the appearance, size and features of your product.

Test the market with your product before production.

Save time and money by identifying and reducing design defects.

Improve and simplify the production process.

Complete parts, ready for immediate use

Easy customization

Suitable for many different substrates

Perfect for making complex geometric shapes

Excellent surface finish

CNC machining tolerance

Brushed metal, PEEK and ULTEM | Other brushed plastics | No drawing | |

| Linear dimension | +/- 0.01 mm +/- 0.0003 inches | +/- 0.05 mm +/- 0.002 inches | ISO 2768 |

aperture (unreamed) | +/- 0.01 mm +/- 0.0003 inches | +/- 0.05 mm +/- 0.002 inches | ISO 2768 |

| Shaft diameter | +/- 0.004 mm +/- 0.00016 inches | +/- 0.05 mm +/- 0.002 inches | ISO 2768 |

CNC turning service

Star Rapid's CNC turning service uses imported highspeed turning centers equipped with dynamic tools and automatic rod feeders. Power tools using imported Guhring tools allow us to perform some milling and crossdrilling functions without the need for multiple machine setups, saving time and money. We often turn brass, aluminum, lowcarbon and stainless steel, and hard plastics. Our CNC turning services create complex external geometry and inner holes with very tight tolerances and excellent surface finish. CNC turning is suitable for rapid prototyping, new product launch and small series production.

CNC milling services

Star Rapid's CNC milling services use imported multiaxis machines controlled by advanced PowerMILL and Vericut software. Highspeed milling is ideal for creating prisms and complex geometry shapes in a wide variety of brasses, mild and stainless steels, aluminum, metal and hard plastics. Advanced Guhring end mills and tools, as well as European management expertise, ensure your parts have tight tolerances and excellent surface finish. Of course, we also offer complete inhouse finishing services for many more product development solutions.

Join us

Apply for a position*

name*

Mobile phone number*

Wechat ID*

mailbox*

Consultation content*

Verification code

- I have read and agree 《Privacy protection agreement》