Surface treatment

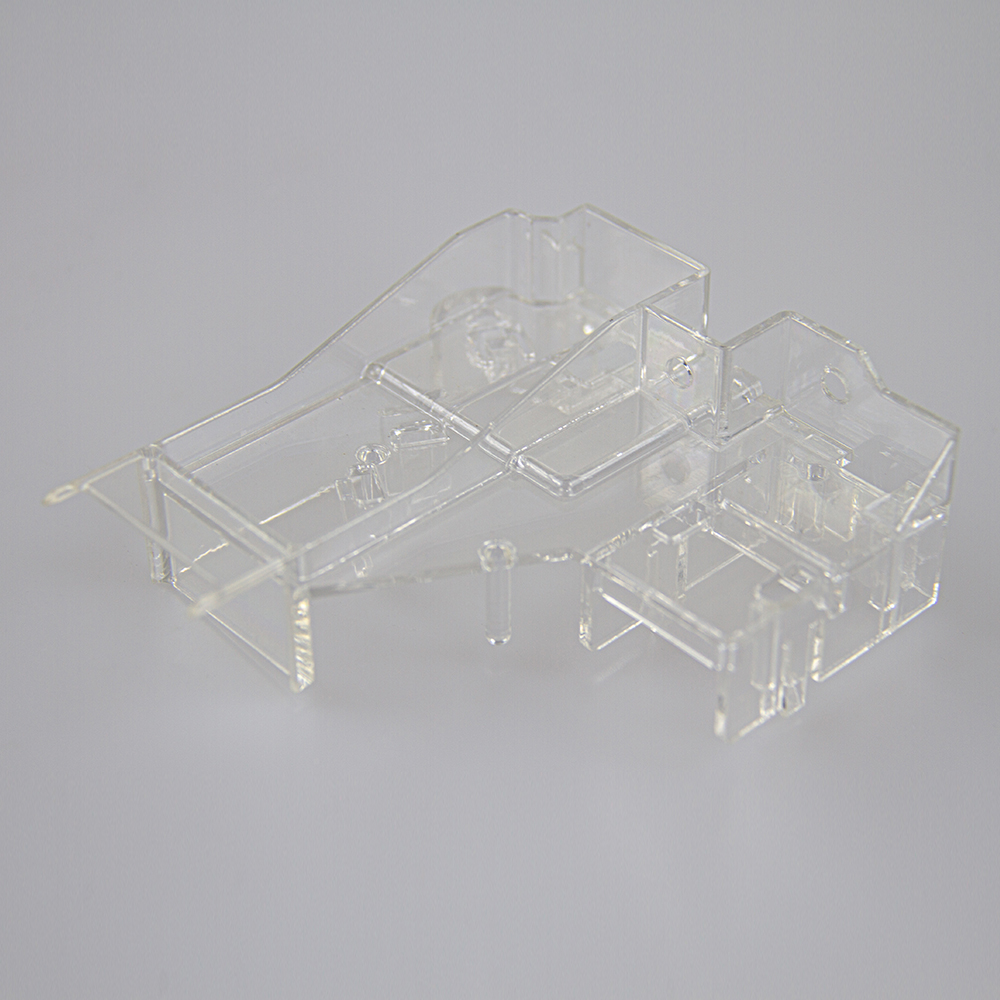

We don't just make parts. We make them even better by applying various treatments to improve their appearance, performance and durability.

Sanding/sandblasting/polishing/oil spraying/painting │/ Silkscreen/drawing/radium carving/electroplating/oxidation

Keyo surface treatment expertise

The Surface Finishing Research and Development department of Keo is a specialized department focused on providing visual finishing solutions. If you have a custom finish for your color, texture, gloss or hardness requirements, Keyo Surface Treatment R&D will work with you to achieve it. If you want clear or translucent shades, sheets of pearl or metal, and painted and cast parts that glow in the dark, we are sure to meet your requirements.

The development of the Keo was led by RP Finishing specialist Bradlee Hughes. Bradlee is a BFA University degree artist and industrial designer from the United States with more than 20 years of professional experience working with designers and engineers worldwide and helping to guide the Keo business staff in effective communication with customers and the internationalization and standardization of production processes.

Join us

Apply for a position*

name*

Mobile phone number*

Wechat ID*

mailbox*

Consultation content*

Verification code

- I have read and agree 《Privacy protection agreement》